Design and Fabrication of Mini Groundnut & Peanut Shelling Machine

Abstract: Groundnut is the sixth most important oilseed crop in the world and it is belongs to beans family. Shelling is a fundamental step in groundnut processing and it can be done by hand or machines. Hand shelling process is labour intensive, slow and tiresome. Numbers of groundnut Sheller machines are available in the market but they are large in size, costly and not suitable for domestic applications, they are best suitable for industrial applications where mass production is required. Hence it is essential to design and fabricate a portable groundnut Sheller machine for domestic application.

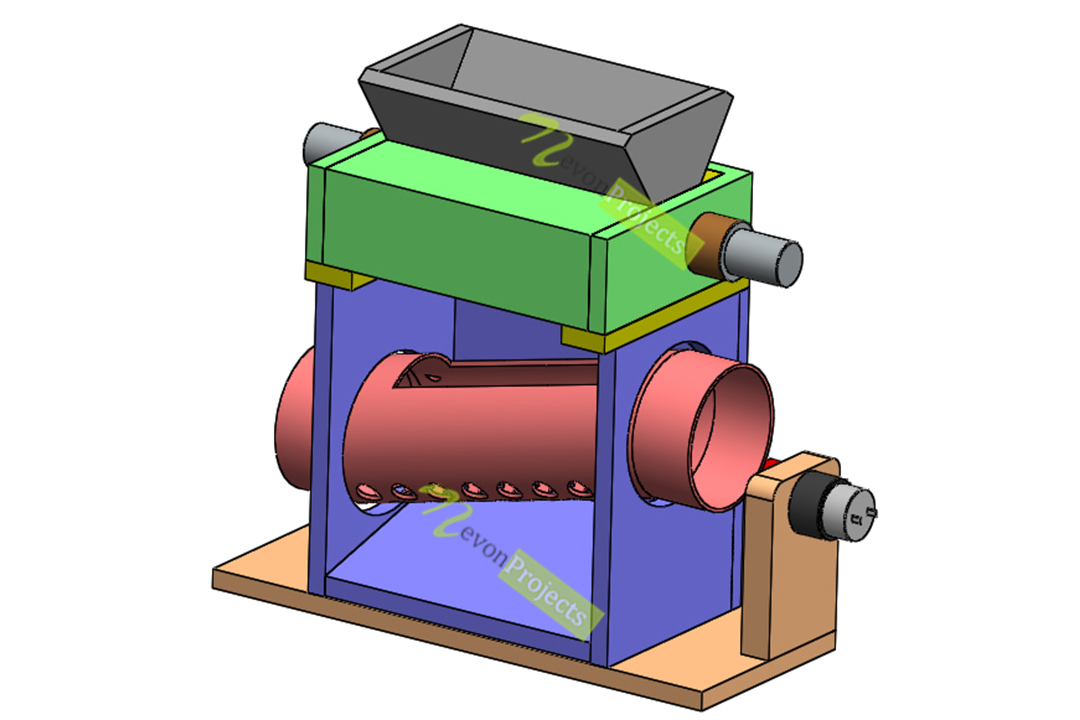

Components:

1. DC motors

2. Wooden frame

3. Hopper

4. Shell remover

Groundnut is one of the most on demand and on increase legume and the application depends on the cleanness of the nuts. As the groundnut seed is surrounded by a pod, which is developed underground, the pod is harvested by pulling and lifting the plant manually or by using the machine. Usually groundnuts are shelled simply by hand using manual method. To separate the nuts from its shell, a shelling machine was designed and developed. This mechanical project aims at designing and fabricating a groundnut shelling machine. The shelling machine is operated using electric DC motors which is connected to the external power supply. When power is supplied to the motors, it rotates the roller which have shell crushing horns. Groundnuts are fed into the crushing chamber through hopper and gets crushed between the semi-circular net and the roller.

Abstract - Groundnut is grown on small scale by farmers in developing countries like India. Lack of groundnut processing machines at affordable cost, especially groundnut Sheller, is a major problem of groundnut production. Numbers of groundnut Sheller machines are available in the market but they are large in size, costly and not suitable for domestic applications, they are best suitable for industrial applications where mass production is required. Hence it is essential to design and fabricate a portable groundnut sheller machine for domestic application. This paper describes about the design of various components of groundnut Sheller machine. Hence in this design of various parts are necessary, and design of various parts due to which the design quality of those parts will be improved. Overall, this project involves processes like design, fabrication and assembling of different components etc. Key Words: Groundnut, peanut, shell, crushing, hopper.

1.INTRODUCTION

Groundnut (Arachis hypogaea) is a species in the legume or beans family ([1], [2], [3]). It was first cultivated in Peru [9]. Its seed contains about 63% carbohydrate, 19% protein and 6.5% oil [1]. Groundnut is the sixth most important oilseed crop in the world. As the groundnut seed is contained in pod, which is usually developed underground, the pod is harvested by pulling or lifting the plant manually or by using the machine. The pods are stripped from the plant, dried, stored and processed. Shelling is a fundamental step in groundnut processing [1]. Shelling can generally be done by hand or machines. As well as the study of manufacturing was very important in order to carry out this project to ensure that what are needs to do. This project involves the process of designing the different parts of this shelling machine considering forces and ergonomic factor for people to use. This project is mainly about generating a new concept of groundnut shell (crush) that would make easier to bring anywhere and easier to crush groundnut. After the design has completed, it was transformed to its real product where the design is used for guideline.

. OBJECTIVE

The main and basic objective is to make low cost groundnut shelling machine.

Another thing is that to shell maximum possible groundnut in shortest possible time.

The machine should not damage the peanuts in according to earn profit.

The cost of a machine should be affordable to the farmers.

Space occupied by the machine should not be so large. It should be kept within the land.

The machine should not have excessive weight. It should be such that it can be easily portable.

. DESIGN AND CALCUTATION

A. Design of V-Belt N1=1440 rpm N2=240 rpm Pd=0.5 HP=372.85 W=0.307285 Kw Droller=14 inch=355.6 mm W=30 kg =30*9.81 =294.3 N Designation of Belt At Pd=0.37285 Kw =372.585 w [P.no. 160 Table XV-8] Designation of belt is “A” 1) Width (w) =13mm 2) Thickness (t) =8mm 3) Pulley Dia. =75mm (D1) Tension factor (kc) =2.52 Calculate power per belt [P.no. 161 table no.XV-9 from B.D.Shivalkar] Power/belt= (Fw-Fc)*(eµƟ/sin (α/2)-1/e µƟ/sin (α/2)*Vp) Where Vp = π*D1*N1/60*1000 =5.65 m/sec µ = coefficient of friction = 0.5 α = cone angle =36 degree α/2 =36/2 =18 Ɵmean= π-(D2-D1/C) =∏-(450-75/525) = 2.43 rad Vp = π*D2*N2/60*1000 5.65 = π*240*D2/60*1000 D2 =450 mm

Centre distance C =D1+D2 =75+450 =525 mm e µƟ/sin (α/2)= e0.3*2.43/sin (18) =10.5 Now, Fw=w2=132=169 Fc= Centrifugal tension (N) = kC*(Vp/5)2 =2.52*(5.65/5)2 = 3.2177 N Power/belt = (169-3.2177)*(10.581-1/10.581)*5.65 Power/belt = 848.146 W/belt To find number of belt (n) n = Pd/power/belt = 372.85/848.146 = 0.43 ≈ 1 Therefore n=1 To find cross section of belt For designation A b= 3.3 mm h= 8.7 mm e= 15 mm f=9-12= 10 To calculate length of belt l= π/2*(D1+D2) +2C+ ((D1-D2) 2/4C) l= π/2*(75+450) +2*525+ ((75-450)2/4*525) l=1941063 mm Width of pulley = (n-1)*e+2f = (8.7-1)*15+2(10) W=135.5mm B. Design for pulley Ds=19mm Calculate hub properties a) Diameter (Dh) = 1.5ds+25 mm = 1.5*19+25 (Dh)=53.5mm (b) Length (lh) =1.5ds =1.5*19 Lh =28.5mm PULLEY=2 Type of construction At d2=450

CONCLUSION The cost of the machine is less and if the farmer buys this machine, farmer can recover the invested money back. By using this machine problem of the labor crises can be reduced. Comparing with manual harvesting only 1 labor is required. It makes the process faster hence reduces most of the shelling time and labor cost. This machine is helpful for both small and big farms.

6. ADVANTAGES

Shelling time will be less

Efficient work is done by using machine

Limited number of labours are required

Cost of shelling is comparably less as manual shelling