ABSTRACT

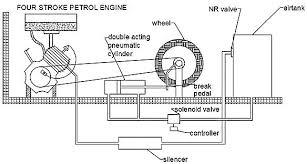

The aim is to design and to develop an air brake system based on exhaust gas is called “fabrication of air brake system using engine exhaust gas”. The main aim of this project is to reduce the workloads of the engine drive to operate the air compressor, because here the compressor is not operated by the engine drive. Here we are placing a turbine in the path of exhaust from the engine. The turbin e is connected to a dynamo by means of coupling, which is used to generate power. Depending upon the airflow the turbine will start rotating, and then the dynamo will also starts to rotate. A dynamo is a device which is used to convert the kinetic energy into electrical energy. The generated power can be stored in the battery and then this electric power has loaded to the D.C compressor. The air compressor compresses the atmospheric air and it stored in the air tank and the air tank has pressure relief valve to control the pressure in the tank. The air tank supplies the compressed pneumatic power to the pneumatic actuator through solenoid valve to apply brake. The pneumatic actuator is a double acting cylinder which converts hydraulic energy into linear motion.

Keyword: - Dynamo, DC Compressor, and Pressure relief valve etc….

INTRODUCTION

BRAKING SYSTEM

A brake is a mechanical device that inhibits motion by absorbing energy from a moving system It is used for slowing or stopping a moving vehicle, wheel, axle, or to prevent its motion, most often accomplished by means of friction.

Most brakes commonly use friction between two surfaces pressed together to convert the kinetic energy of the moving object into heat, though other methods of energy conversion may be employed. For example, regenerative braking converts much of the energy to electrical energy. which may be stored for later use. Other methods convert kinetic energy into potential energy in such stored forms as pressurized air or pressurized oil. Eddy current brakes use magnetic fields to convert kinetic energy into electric current in the brake disc, fin, or rail, which is converted into heat. Still other braking methods even transform kinetic energy into different forms, for example by transferring the energy to a rotating flywheel.

Brakes may be broadly described as using friction, pumping, or electromagnetics. One brake may use several principles: for example, a pump may pass fluid through an orifice to create friction:

Frictional brakes are most common and can be divided broadly into "shoe" or "pad" brakes, using an explicit wear surface, and hydrodynamic brakes, such as parachutes, which use friction in a working fluid and do not explicitly wear. Typically the term "friction brake" is used to mean pad/shoe brakes and excludes hydrodynamic brakes, even though hydrodynamic brakes use friction. Friction (pad/shoe) brakes are often rotating devices with a stationary pad and a rotating wear surface. Common configurations include shoes that contract to rub on the outside of a rotating drum, such as a band brake; a rotating drum with shoes that expand to rub the inside of a drum, commonly called a "drum brake", although other drum configurations are possible; and pads that pinch a rotating disc, commonly called a "disc brake". Other brake configurations are used, but less often. For example, PCC trolley brakes include a flat shoe which is clamped to the rail with an electromagnet.

CIRCUIT DIAGRAM

https://www.mifratech.com/public/

https://www.mifratech.com/public/

https://www.facebook.com/mifratech.lab

https://twitter.com/mifratech