Abstarct

The rapid growth in the population has also led to the surge in the volume of waste being generated on a daily basis. This increase in the generation of waste due to continuous growth in the urbanization and industrialization has become a severe problem for the local and the national government. It is also posing a serious problem for the local authorities to manage the wastes being dumped everywhere as landfill. To ensure the minimal risk to the environment and human health, it is necessary to take meticulous measures when segregating and transporting waste. Segregation of waste in a proper manner brings to the limelight actual economic value of the waste. The traditional method used for segregating of waste in India is through rag pickers which are time-consuming and can have adverse effects on the health of the people who are exposed to such wastes. Here we propose the use of an Auto Waste Segregator dust bin which is cheap and also an easy to use solution for segregation of household waste. It is designed to segregate the waste into two categories viz. Dry and wet waste. The system makes use of moisture sensor for the segregation of wet and dry waste and an LCD display for displaying the result of segregation. It is evident from experimental reports that segregation of waste using auto waste segregation has been successful.

Working Principle:

The working principle of the project is as follows:

When we supply the power to the micro controller the ir sensor ultrasonic sensor dry wet detection sensors are get powered up. The waste enters the conveyer belt motor turns on.

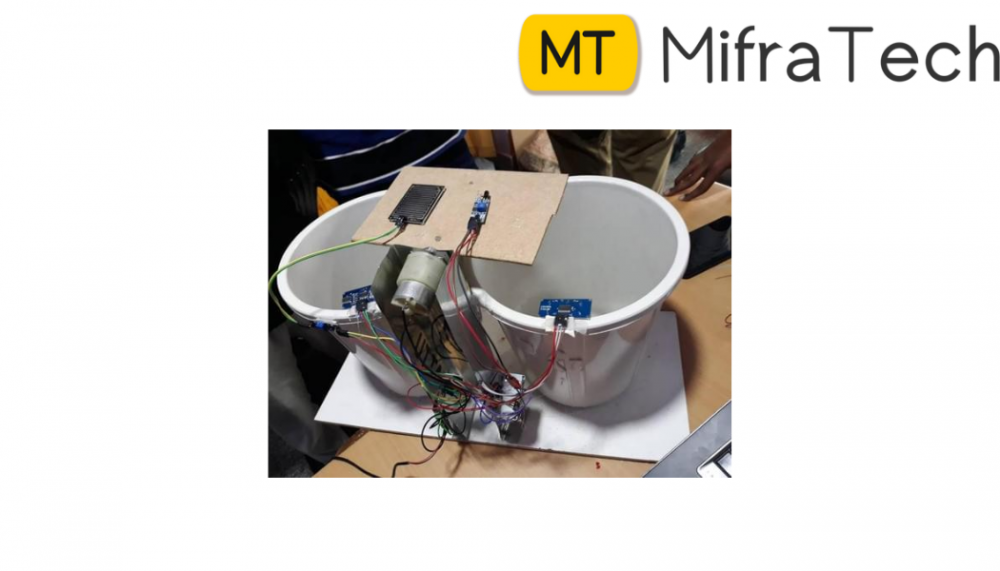

The waste is sensed by the moisture sensor that weather it is dry waste or wet waste. If the waste has some humidity it is detected as wet waste and relay will turned on towards right side and the waste is pushed into the wet waste bin. Or else dry waste will be detected and the servo motor will be turned towards left and the waste will be pushed towards the dry bin. And the information about the dry or wet and metal waste will be displayed in the blynk app and the level waste in both the bin can be detected using the ultrasonic sensor and will be displayed in the blynk app , Finally the wastes are dropped into the respective bins and the segregation process is completed.

OBJECTIVE

Waste management or waste disposal are all the activities and actions required to manage waste from its inception to its final disposal in proper place. This includes amongst other things collection, transport, treatment and disposal of waste together with monitoring and regulation. It also encompasses the legal and regulatory framework that relates to waste management encompassing guidance on recycling. In this system the wastage is collected from the running train. The sensor is sense the availability of wastage in the tank and send to cloud computing .the station master will read the wastage level in the tank from the cloud computing and arrange for disposal .They will control the tap through the wifi technology

Block diagram of the project/concept:

Conclusion:

Implementation of this system at a local level like societies, educational institutes, etc. can reduce the burden on the local authorities. The automatic waste segregator is one small step towards building an efficient and economic waste collection system with a minimum amount of human intervention and also no hazard to human life. Using a conveyor belt makes the system far more accurate, cost-effective and also easier to install and use at a domestic level. Segregating all these wastes at a domestic level will also be time-saving. While implementing our system we came across many problems like, the accuracy of the moisture sensor, adjusting the range of ultrasonic sensors and some more, but using some modifications we tried the make the system as reliable as possible

Project links:

www.mifratech.com/public

www.mifraelectronics

www.shieldtechno.com

https://mifratech.com/public/pdf_files/IMAGE%20PROCESSING%20PROJECT%20LIST.pdf

https://mifratech.com/public/pdf_files/IMAGE%20PROCESSING%20PROJECT%20LIST.pdf

https://mifratech.com/public/pdf_files/IOT%20AND%20EMBEDDED%20SYSTEM%20PROJECT%20LIST.pdf

https://mifratech.com/public/pdf_files/ROBOTICS%20PROJECT%20LIST.pdf

www.alphaengineeringprojects.com

https://www.youtube.com/channel/UCVBnP3kN_dRKa4gXzrfBcqQ

mifratech youtube channel for educational purposes

https://www.facebook.com/mifratech.labs

https://www.instagram.com/mifratech/

https://www.linkedin.com/company/mifratech/?originalSubdomain=in

https://twitter.com/mifratech

best project centre for electronics students

engineering project centre for cse

best projects in yelahanka

nearby project developement centre

yelahanka project centre

yelahanka engineering project centre

best embedded project for embedded system

electronics components

festival offers for electronics components

festival offers for electronics and electrical engineering project

engineering project centre in yelahanka

best projects for ece

final year engineering project for embedded in yelahanka

engineering project centre in gulabarga

enginerering projects in banaglore