Pneumatic Sand Filtering Project

Pneumatic Sand Filtering Project

Abstract -

The Modified Drawer Compacted Sand Filter (MDCSF) is a modified design for a drawer compacted sand filter in which the sand layer, is broken down into several layers , each of which is 10 cm high and placed in a movable drawer separated by a 10 cm space. A lab-scale DCSF was designed and operated for 60 days fed by synthetic grey water. The response of drawer compacted sand filters and modified drawer compacted sand filter in terms of COD, BOD5, Hardness, turbidity and TDS reductions were evaluated. Each loading regime was applied for 30 days. Results showed that DCSF was able to remove > 91% of organic matter and Total Suspended Solids for all doses. Significant reduction in BOD5 (100%) and COD (95%) was noticed after water drained through the modified drawer compacted sand filter. This paper concludes that MDCSF would be appropriate for use in dense urban areas as its footprint is small and is appropriate for a wide range of users because of its convenience and low maintenance requirements. Key Words: Drawer compacted sand filter, grey water filter, synthetic grey water , Modified drawer compacted sand filter

1.INTRODUCTION

Water covers 70 percent of the globe’s surface, but most is saltwater. Freshwater covers only 3 percent of the earth’s surface and much of it lies frozen in the Antarctic and Greenland polar ice. Freshwater that is available for human consumption comes from rivers, lakes and underground sources and aquifers. Together these sources account for just one percent of all water on earth. The world’s fresh water sources are threatened by climate change. Scientists around the world agree that recent climate changes occurring globally are the result of human activities. Rising global temperatures lead to heightened risk of more extreme and frequent floods and drought. Water scarcity currently affects many region in the world. In water rich countries, urbanization and industrialization have frequently led to contaminated and deteriorated surface water and ground water such that these countries are unable to meet the ever increase water demand. The UN’s climate change panel stated that the world’s current population of about 6.6 billion is forecast to rise by 2.5 billion by 2050. As human population increases, the need for water also increases in domestic, agricultural, industrial and urban sectors. Consequently, water or ‘blue gold’ is widely predicted to be a critical resource. In 2009, the symposium on water security organized by the World Water Organization warned that two-third of the world’s population will face water shortage by 2050.

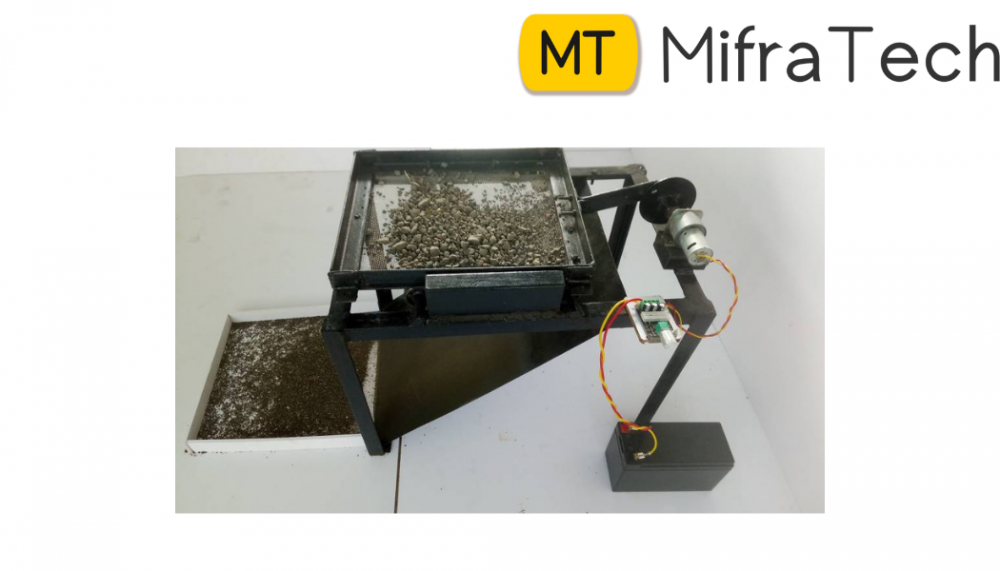

Pneumatic Sand Filtering is used to remove metal chips, stones, nails, and so forth from elaboration sand which is utilized for casting purpose and development works. Filtering is done manually which takes out unwanted parts from construction sand. In order to reduce timing and do the process effectively, we are going to fabricate a pneumatic sand filter which works using pneumatic mechanism. The main objective of the compressor is to produce high pressurized air which is used to activate the cylinder. The air from the compressor is pumped with high pressure. The pneumatic actuator is connected to a filter frame with mesh below and with enclosing frame on the sides. As we start the sand filter system, the actuator pulls the frame forward and backward so that a mesh strainer, isolates the sand for the construction work.

Components

CONCLUSIONS

Results and Discussion The performance of Drawer Compacted Sand Filter (DCSF) in the grey water treatment was studied and compared with DCSF with silver coated sand and the results of the study are reported as follows. Parameter Unit Concentration COD mg/l 210 BOD mg/l 18.2 pH - 6.18 Turbidity NTU 5 Hardness mg/l 270 TDS mg/l 535.73

Characteristics of synthetic grey water Table 4.2: Experimental data of DCSF with uncoated sand High removal efficiency can be seen in DCSF filter. Because, Drawer Compacted Sand Filter through dividing the sand depth into several layers and allowing air space between layers would ease the diffusion of oxygen between different layers so that the filter will function with fully aerobic conditions, thus enhancing the aerobic biological treatment of grey water and increase the treatment efficiency. For the survival of the microorganisms within the biological zone, there needs to be a supply of oxygen. Oxygen is used in the metabolism of biodegradable components and the inactivation and consumption of pathogens. If it falls to zero during filtration anaerobic decomposition occurs, with consequent production of hydrogen sulphide, ammonia, and other taste- and odour-producing substances together with dissolved iron and manganese, which make the treated water unsuitable for washing clothes.

IEEE PROJECTS | ECE best projects bangalore, CSE engineering projects , eee projects, data science best final year projects, projects ideas, engineering project center, web development projects, embedded final year best projects, mini projects

2128, Srinidhi complex, 3rd floor,16th B cross,

Bus stand road, near mother dairy cross, Yelahanka new town

BANGALORE, Karnataka 560064

We are providing best quality on projects with good services. We are giving free internship on project, Projects Based on IOT, Agriculture, Robotics, Pneumatics and Hydraulics, Aeronautical

Mifratech websites : https://www.mifratech.com/public/

Mifratech facebook : https://www.facebook.com/mifratech.lab

Mifratech instagram : https://www.instagram.com/mifratech/

Mifratech twitter account : https://twitter.com/mifratech

Contact for more information : [email protected] / 080-73744810 / 9972364704

final year mechanical engineering project

final year mechanical engineering projects

final year mechanical engineering projects pdf

final year mechanical engineering project presentation ppt

final year mechanical engineering project report pdf

low cost final year mechanical engineering projects

final year project mechanical engineering politeknik

final year project mechanical engineering ppt

final year project proposal mechanical engineering

mechanical engineering final year project analysis

mechanical engineering final year project on agriculture

mechanical engineering final year project boiler

best final year project for mechanical engineering

final year mechanical project

final year mechanical engineering projects free download

mechanical engineering final year project pdf download

mechanical engineering final year projects on automobile

easy mechanical engineering final year projects

mit final year projects mechanical engineering