Now a day’s energy is one of the most important issues around the world. Especially in Bangladesh energy crisis is a big problem. Renewable energy sources can be a great media to solve this energy crisis problem in Bangladesh. As we know natural resources will finish one day. That’s why researchers are trying to introduce substitute energy sources from nature. That must be green and not harmful for the environment.

Energy harvesting is defined as capturing minute amounts of energy from one or more of the surrounding energy sources. Human beings have already started to use energy harvesting technology in the form of windmill, geothermal and solar energy. The energy came from natural sources, termed as renewable energy. Renewable energy harvesting plants generate kW or MW level power; it is called macro energy harvesting technology.

Moreover, micro energy also can produce from those natural sources that are called micro energy harvesting. Micro energy harvesting technology is based on mechanical vibration, mechanical stress and strain, thermal energy from furnace, heaters and friction sources, sun light or room light, human body, chemical or biological sources, which can generate mW or μW level power. Micro power supply needs is increasing greatly with time as our technology is moving to the micro and nano fabrication levels.

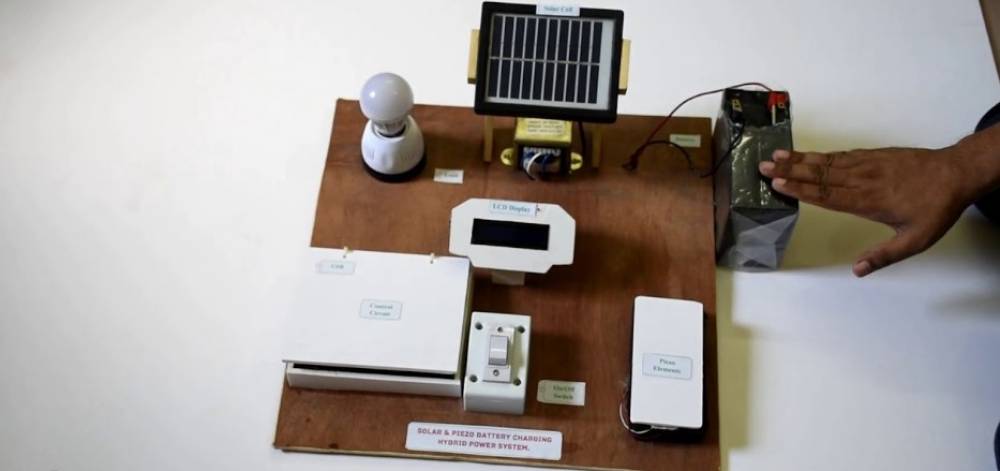

The main objective of this work is to develop a Solar Piezo Hybrid Power Charging System which works in a wellorganized manner with respect to Micro energy harvesting technology which is based on mechanical vibration, mechanical stress and strain, thermal energy from furnace, heaters and friction sources, sun light or room light, human body, chemical or biological sources, which can generate mW or W level power. Micro power supply needs is increasing greatly with time as our technology is moving to the micro and Nano fabrication levels. Our discussion on this is based on generating micro energy from vibration and pressure using piezoelectric material.

This day most of the research in the energy field is to develop sources of energy for future. It is time to find renewable sources of energy for the future. Piezoelectric materials are being more and more studied as they turn out to be very unusual materials with very specific and interesting properties. In fact, these materials have the ability to produce electrical energy from mechanical energy for example they can convert mechanical behavior like vibrations into electricity. Such devices are commonly referred to as energy harvesters and can be used in applications where outside power is unavailable and batteries are not feasible option. While recent experiments have shown that these materials could be used as power generators, the amount of energy produced is still very low, hence the necessity to optimize them. Piezoelectric materials have two properties that are define as direct and converse effect. Direct effect is the property of some materials to develop electric change on their surface when mechanical stress is exerted on them, while converse effect is the property of some materials to develop mechanical stress when an electric charge is induced.

CONCLUSION

The purpose of this project was to establish the feasibility of a roadside hybrid energy collection/recovery system that can then be used for running nearby street utilities such as lights/signals. The hybrid sources are solar energy (harvested by a commercially available solar cell located next to roadway) and piezoelectric energy (harvested by an array of piezoelectric elements next to the roadway). Each of these systems had its own component level controller. A practical ratio of cost-effective energy recovery from these two sources had been sought in the design of the supervisor controller. It should be possible to monitor system performance via a wireless display located a safe distance from the energy harvesting equipment.

Note : Find the best solution for electronics components and technical projects ideas

keep in touch with our social media links as mentioned below

Mifratech websites : https://www.mifratech.com/public/

Mifratech facebook : https://www.facebook.com/mifratech.lab

mifratech instagram : https://www.instagram.com/mifratech/

mifratech twitter account : https://twitter.com/mifratech

Contact for more information : [email protected] / 080-73744810 / 9972364704